Durability, agility and aerodynamic efficiency are integral to the ZAS unmanned systems. To achieve this synergy, the company’s composite structure manufacturing employs advanced lightweight material. This ensures that the flight characteristics are optimized and structural integrity maintained. Rigorous stress testing and military-grade quality control ensure that the drones reliably endure extreme operable conditions.

Advanced Composites Manufacturing

Modern day composite materials have significantly bolstered aerospace manufacturing industry due to their reliability, durability and superior strength-to-weight ratio. The implementation of these advanced manufacturing techniques in significantly boosts the performance, stability and efficiency of the aerial systems we produce.

These techniques enable us to create complex geometries and intricate aerofoil designs, which would be challenging to accomplish using traditional manufacturing methods. The result is lightweight yet robust structures for various parts of the aircraft, including the fuselage, wings, and tail.

This approach enhances the capabilities of our Unmanned Aerial Vehicles (UAVs), enabling longer flight times, increased payload capacity, and improved manoeuvrability. Furthermore, the use of advanced composites contributes to a longer operational lifespan for our drones, which are built to withstand harsh conditions

Aerodynamic Design

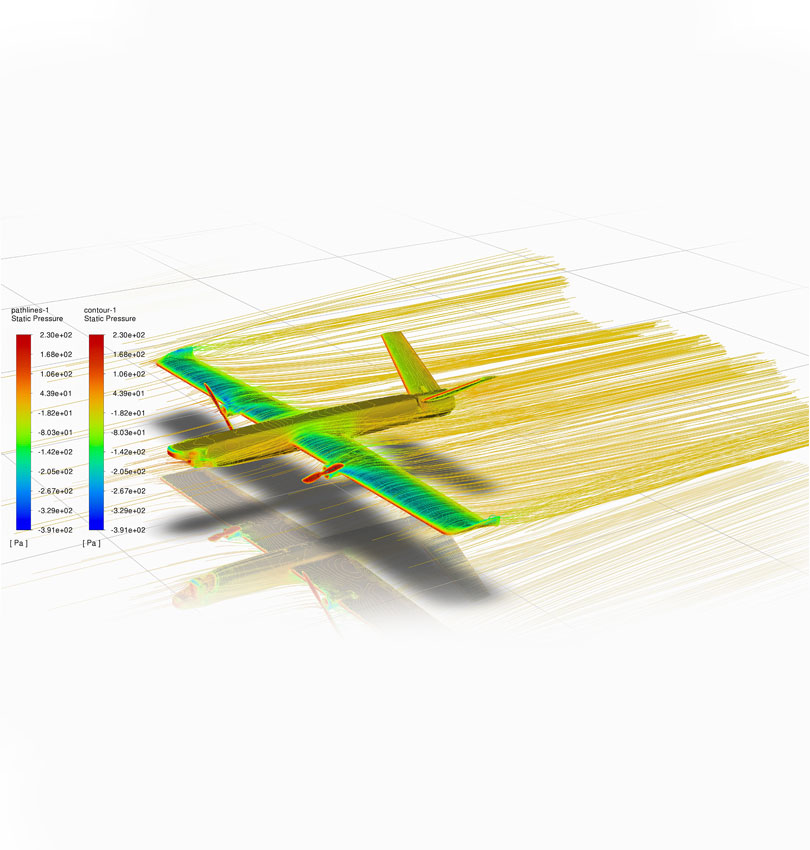

Precision Design: Merging Aerodynamics and CFD.

- Our high-performance aerial platforms rely on a synergy of Aerodynamic Design principles and Computational Fluid Dynamics (CFD). These advanced technologies offer critical insights into specific components and subsystems behaviour.

- Our fixed-wing designs prioritize stealth. Their sleek contours minimize acoustic signatures, ensuring discreet operation during critical tasks. Whether it's border surveillance, rapid response, or covert reconnaissance, our drones gather intelligence discreetly without compromising security.

- Behind the scenes, our engineers employ CFD simulations to understand airflow around our drones. We optimize wing profiles, control surfaces, and vortex shedding, resulting in exceptional stability even in challenging weather conditions.

- The intricacies of our designs leverage the optimisation of both form and function. Our UAV’s aren’t just eyes; they’re intelligence hubs.

- The recent High Altitude Flight Performance Test—conducted at 4500 meters AMSL in Nubra Valley, Ladakh—demonstrated our commitment to agile design and endurance. From thermal imaging to multispectral analysis, our drones decode landscapes, capturing crystal-clear imagery while remaining inconspicuous. It’s not just surveillance; it’s foresight.